In the rapidly evolving world of high-performance applications, efficient thermal management is paramount. As systems become increasingly powerful, the demand for effective cooling strategies has never been greater. High-performance computing, automotive engineering, and advanced electronics all require innovative cooling solutions to ensure optimal performance and longevity.

Modern cooling systems must not only dissipate heat but also operate under strict energy constraints. Conventional cooling methods are often insufficient for high-performance environments, necessitating the exploration of cutting-edge techniques. Liquid cooling, for instance, provides superior thermal conductivity compared to air cooling, enabling tighter thermal design and more compact system layouts.

Moreover, the integration of phase change materials and novel heat sink designs can significantly enhance cooling efficiency. These strategies must be tailored to the specific requirements of each application to maximize efficiency while minimizing energy consumption. Understanding these diverse cooling strategies is critical for engineers and designers tasked with developing the next generation of high-performance systems.

Optimizing Liquid Cooling for High-Performance CPUs

Liquid cooling has emerged as a vital solution for managing the thermal output of high-performance CPUs, especially in environments where maximum efficiency and performance are paramount. To optimize liquid cooling systems for these demanding applications, several key factors must be considered.

System Design: The architecture of the cooling setup plays a crucial role. A well-designed system should minimize the length and bends of tubing to reduce flow resistance. Utilizing larger diameter tubing can also enhance the flow rate, ensuring efficient heat transfer. Additionally, strategically placing the pump closer to the CPU can further improve performance by increasing coolant circulation speed.

Coolant Selection: The choice of coolant is critical for achieving optimal heat dissipation. Many systems utilize a mixture of deionized water and specialized additives to prevent corrosion and enhance thermal conductivity. Other options, such as glycol-based solutions, can provide better freeze protection but may have lower thermal conductivity. Evaluating the specific needs of the system will guide the selection of the best coolant.

Heat Exchanger Efficiency: The effectiveness of radiators is integral to the overall cooling performance. Using high-quality radiators with a greater surface area allows for better heat dissipation. Additionally, utilizing a fan configuration that maximizes airflow and minimizes noise can lead to improved operational efficiency. Incorporating multiple radiators in parallel can also distribute thermal loads more evenly.

Monitoring and Control: Integrating temperature sensors and flow meters into the liquid cooling system allows for real-time monitoring of performance. Implementing adaptive cooling strategies that automatically adjust pump speed and fan operation based on workload can lead to significant energy savings while maintaining optimal CPU temperatures. Advanced control systems can predict cooling requirements based on workload intensity, further enhancing efficiency.

Maintenance Practices: Regular maintenance is essential for reliable operation. This includes checking coolant levels, monitoring for leaks, and replacing aged components such as pumps and radiators. Flushing the system periodically to remove sediment and contaminants will ensure that thermal performance remains consistent over time.

By addressing these critical components, high-performance liquid cooling systems can be significantly optimized, promoting enhanced thermal management, improved performance, and extended hardware lifespan.

Implementing Advanced Airflow Management Techniques

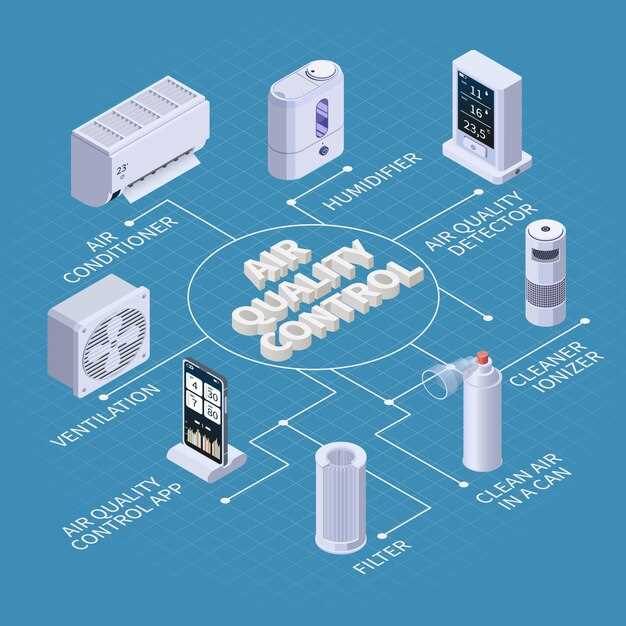

Effective airflow management is crucial for optimizing the cooling performance of high-performance systems. By controlling and directing airflow, one can enhance heat dissipation and maintain lower operational temperatures. This section outlines several advanced techniques to implement efficient airflow management.

1. Optimized Air Intake and Exhaust Design: The foundation of airflow management lies in the design of intake and exhaust points. Positioning air intakes in cooler areas and utilizing exhaust vents that promote unobstructed airflow can significantly improve thermal performance. In many systems, angled or contoured ducts can reduce turbulence, facilitating smoother airflow pathways. Additionally, incorporating high-efficiency filters at air intakes ensures that only clean air enters the system, minimizing potential blockages.

2. Utilizing Computational Fluid Dynamics (CFD): CFD simulations can be invaluable for visualizing airflow patterns within a cooling system. These simulations allow engineers to identify areas of stagnant air and potential hot spots, leading to informed decisions on the placement of components. By tweaking designs based on CFD findings, one can forecast airflow behaviors under various operational conditions, thus optimizing thermal management strategies.

3. Active Airflow Control Systems: Incorporating adjustable fans and variable speed control mechanisms can enhance airflow management. Smart controllers monitor system temperatures in real-time, adjusting fan speeds according to cooling needs. By implementing thermal sensors, airflow can be dynamically redirected to areas requiring immediate cooling, thus improving efficiency and reducing energy consumption.

4. Strategic Component Layout: The arrangement of components within a high-performance system directly affects airflow efficiency. Using a modular layout can prevent airflow obstruction and allow for better integration of cooling solutions. Grouping heat-producing components together can reduce localized heat density and enable more efficient thermal management through per-component cooling strategies.

5. Insulation and Airflow Barriers: Utilizing insulating materials can help maintain a controlled environment within the system. Airflow barriers can effectively channel cold air directly to critical components while preventing hot air recirculation. Implementing these barriers not only prevents thermal bleed but also maximizes the efficiency of cooling solutions.

6. Regular Maintenance and Monitoring: Advanced airflow management isn’t a one-time effort; it requires ongoing maintenance. Regularly inspecting and cleaning air filters, ducts, and fans ensures optimal airflow. Additionally, employing monitoring systems can alert operators to airflow disruptions, allowing for timely interventions before significant overheating occurs.

Incorporating these advanced airflow management techniques can lead to significant improvements in the thermal performance of high-performance applications. By applying a combination of strategic design, real-time monitoring, and maintenance practices, systems can achieve enhanced reliability and longevity.

Integrating Phase Change Materials for Thermal Regulation

Phase change materials (PCMs) are innovative substances that can absorb, store, and release thermal energy during the process of phase transitions, such as melting and solidifying. Their integration into cooling systems for high-performance applications serves as an effective strategy for enhancing thermal regulation and improving overall efficiency.

The primary advantage of PCMs lies in their ability to maintain specific temperature ranges by leveraging latent heat. As temperature rises, PCMs absorb excess heat, transitioning from solid to liquid. Upon cooling, they release stored heat as they revert to solid form. This property provides a sustainable way to manage thermal loads, which is critical in applications like data centers, electric vehicles, and aerospace systems.

Implementing PCMs in cooling systems can significantly reduce the frequency and intensity of peak thermal loads. For instance, in data centers, the integration of PCMs can alleviate the need for constant air conditioning by stabilizing temperature fluctuations. By lessening the load on traditional cooling systems, energy consumption can be dramatically lowered, contributing to more sustainable operational practices.

The selection of appropriate PCMs is crucial. Materials such as paraffin wax, hydrated salts, and fatty acids exhibit distinct temperature ranges and thermal conductivity properties, making them suitable for specific applications. High-performance applications often require PCMs with high thermal conductivity to ensure rapid heat exchange and effective thermal buffering.

Moreover, the encapsulation of PCMs can enhance their effectiveness by allowing for better integration into existing cooling systems. Encapsulated PCMs can be embedded within the structure of thermal management devices, such as heat sinks or thermal pads, enhancing their ability to transfer heat away from critical components. This strategy not only maximizes surface area but also minimizes the risk of leakage and degradation.

Integration of PCMs also necessitates careful thermal management and monitoring systems to optimize their performance. Advanced control algorithms can be deployed to manage the thermal response of PCMs strategically, ensuring that temperature variations remain within acceptable limits while maximizing energy efficiency. These systems may include sensors and feedback loops that adjust cooling strategies based on real-time thermal data.

In conclusion, integrating phase change materials into thermal regulation strategies represents a promising approach for high-performance applications. By effectively managing thermal loads, PCMs contribute to energy efficiency and stability, paving the way for more sustainable technologies in demanding environments.