When embarking on the journey of assembling a new chassis, a precise understanding of setup is critical for ensuring optimal performance and longevity. The chassis serves as the foundational structure of any vehicle, impacting both handling and stability. Proper attention to detail during the initial assembly phase lays the groundwork for future adjustments and enhancements.

To achieve the best results, it is essential to consider various parameters, including geometry, weight distribution, and alignment. Each of these factors plays a significant role in the overall dynamics of a vehicle. Attention to these elements during the initial assembly can prevent issues that may arise later, saving time and resources in the long run.

This guide aims to provide practical recommendations and actionable insights for setting up your chassis effectively. Whether you’re a beginner or an experienced builder, understanding the foundational principles outlined here will help you navigate the complexities of chassis assembly. Embrace the process, and you’ll be well on your way to creating a high-performance machine.

Choosing the Right Chassis for Your Project

Selecting the appropriate chassis for your project is a crucial step that can significantly influence the overall performance and functionality of your build. Begin by assessing the specific requirements and objectives of your project. Consider the factors such as size, weight, and intended use to ensure compatibility with your components and design.

Size and Form Factor: Evaluate the dimensions of your components, including motors, batteries, and electronic systems. A chassis that is too small may not accommodate all necessary parts, while one that is excessively large can lead to unnecessary weight and complexity. Ensure the chassis size aligns with the scale of your project, whether it’s a small robot or a larger vehicle.

Weight Considerations: The weight of the chassis plays a pivotal role in the overall performance. A lighter chassis can enhance speed and agility, while a heavier one may improve stability and durability. Assess the materials used in the chassis construction; options like aluminum, carbon fiber, or plastic each have their benefits and drawbacks related to strength and weight.

Intended Use: Reflect on the environment in which the chassis will operate. For off-road applications, a robust chassis designed to handle rough terrains may be required. Conversely, for indoor applications, a more lightweight and maneuverable chassis could be better suited. Adapt your choice based on whether your project is intended for racing, exploration, or educational purposes.

Customization and Modularity: Some projects require flexibility in design. If your project may undergo future modifications or upgrades, opt for a modular chassis that allows for easy alteration. This can be crucial as technology advances or as new components become available.

Cost Considerations: Finally, budget limitations can affect your chassis choice. Explore options within your price range while balancing quality and performance. Sometimes, investing in a higher-quality chassis can save costs in the long run by reducing maintenance and improving reliability.

By carefully evaluating these factors, you can choose a chassis that not only meets the functional needs of your project but also enhances its overall performance and efficiency.

Essential Tools and Equipment for Chassis Assembly

When assembling a chassis, having the right tools and equipment is crucial for ensuring precision and reliability. Below is a list of essential items that you should have on hand.

1. Torque Wrench: This tool is vital for applying the correct torque to bolts and fasteners. A torque wrench ensures that components are securely fastened without being over-tightened, which can lead to damage or failure.

2. Socket Set: A comprehensive socket set, including both metric and standard sizes, will allow for efficient assembly of nuts and bolts. Look for a set that includes different drive sizes for versatility.

3. Screwdrivers: A variety of screwdrivers, including flat-head, Phillips, and Torx, is essential for securing smaller components. A magnetic tip can be particularly useful for handling screws in tight spaces.

4. Allen Wrenches (Hex Keys): Many chassis components are secured with Allen screws. A complete set of Allen wrenches in various sizes will facilitate easy assembly and adjustments.

5. Pliers: Needle-nose, cutting, and standard pliers are necessary for gripping, bending, and cutting wires or small components during assembly.

6. Level: Ensuring that the chassis is perfectly level is critical for optimal performance. A good spirit level will help you achieve this during assembly.

7. Measuring Tape: Accurate measurements are essential when aligning components. A reliable measuring tape will assist in ensuring that all parts fit as intended.

8. Safety Equipment: Always prioritize safety by using protective gloves and eyewear. This personal protective equipment will safeguard against potential injuries during assembly.

9. Workbench and Vise: A sturdy workbench provides a secure and spacious environment for assembly. A vise can hold components steady while you work, enhancing precision.

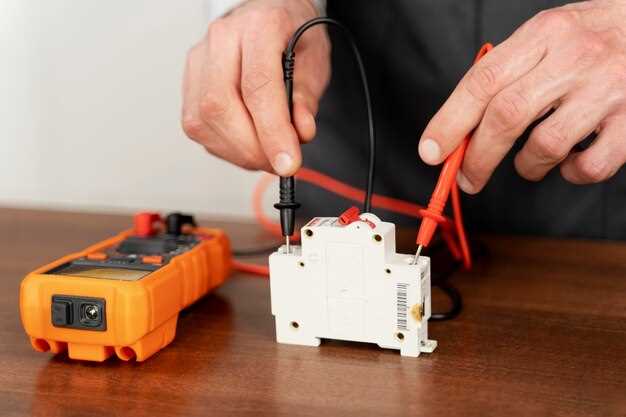

10. Electrical Tools: If your chassis assembly involves any wiring or electrical components, a wire stripper, crimping tool, and multimeter are essential for correct electrical connections.

Having these tools readily available will significantly improve the efficiency and quality of your chassis assembly process. Each tool plays a specific role, and their combined use ensures a successful assembly outcome.

Step-by-Step Procedure for Aligning and Securing Components

Begin by gathering all necessary tools and components required for the assembly. Ensure that you have a torque wrench, alignment tools, and fasteners readily available.

Start with a clean workspace to avoid losing small parts and creating unnecessary complications. Lay the chassis on a flat surface, ensuring that it is stable and won’t shift during the aligning process.

Next, position the main components, such as the engine, transmission, and suspension assembly, on the chassis. Use alignment tools like a straight edge or spirit level to check that all components are correctly oriented and aligned with each other.

When placing components, begin with the heaviest part, typically the engine. Secure it in place with the mounting bolts loosely without fully tightening them. This allows for minor adjustments later on.

Once the engine is in place, move on to the transmission. Align it with the engine using dowel pins or alignment tools specific to your setup. Secure it loosely as well before making further adjustments.

Proceed to install the suspension components. Ensure that the axles and wheels are in alignment with the chassis by examining the distance from the chassis frame to the wheel assembly. Adjust as necessary to achieve proper alignment, then secure these components with the appropriate fasteners.

After securing the suspension, check the alignment again. Use a plumb bob or laser alignment tool to ensure that everything lines up correctly. Make adjustments if needed prior to the final tightening of any fasteners.

Once all components are aligned, start tightening bolts to the manufacturer’s specified torque settings. Begin with the main components and work your way outwards to the smaller parts. This systematic approach ensures even pressure distribution and reduces the risk of warping the chassis.

After all components are securely fastened, perform a final inspection. Verify that all fasteners are tightened adequately, and ensure no components interfere with one another’s operation.

Lastly, conduct a thorough review of the assembly to confirm that nothing has been overlooked. Proper alignment and securing of components are crucial for optimal performance and safety.